In furniture and cabinet manufacturing, complexity is the cost of doing business - but it doesn’t have to hold you back.

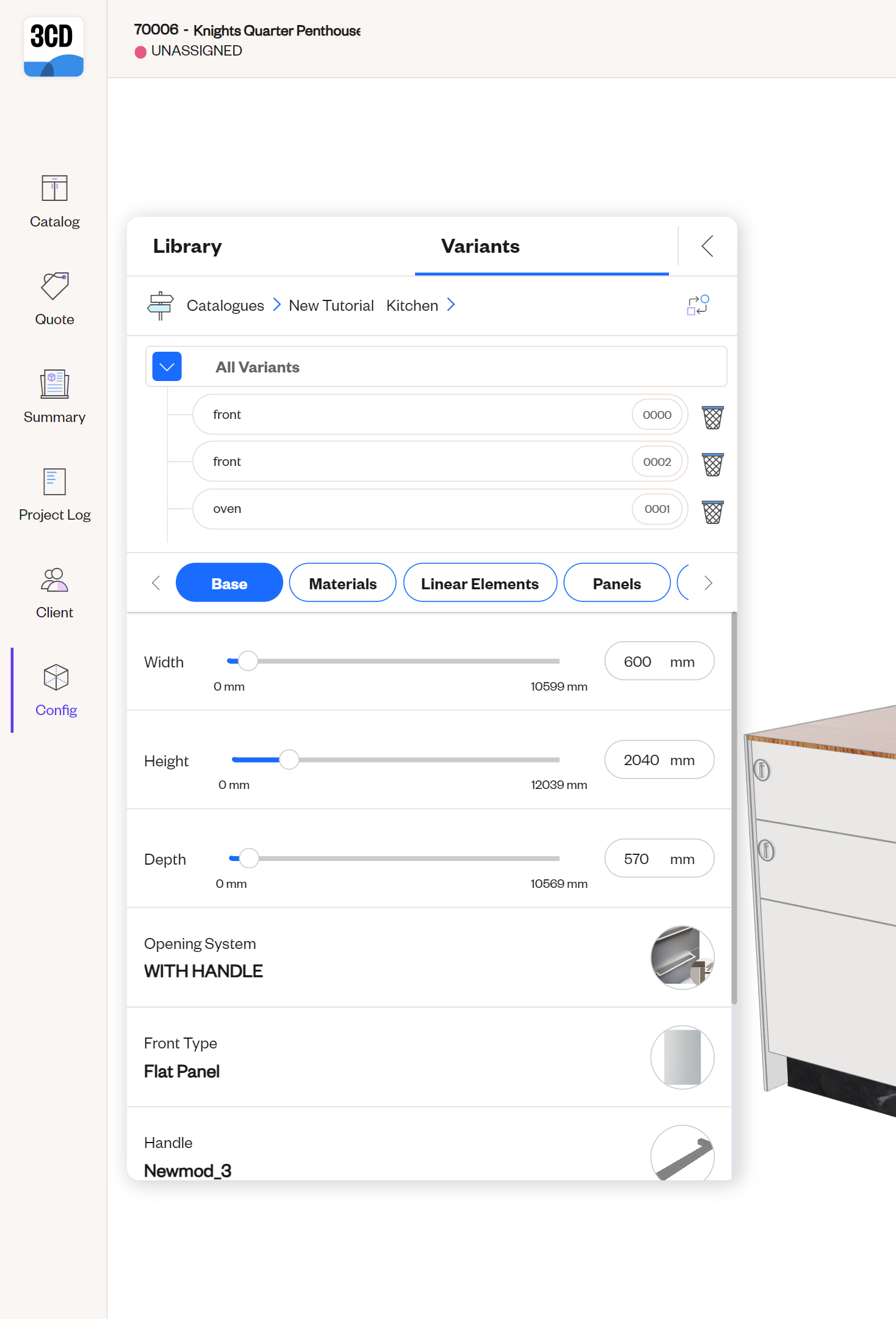

Cabinet manufacturing today demands more than craftsmanship. Customers expect personalized designs, quick turnaround, and consistent quality - whether they buy through a showroom, retailer, or online. To meet these expectations, manufacturers need more than disconnected tools. They need one platform that manages the entire process.

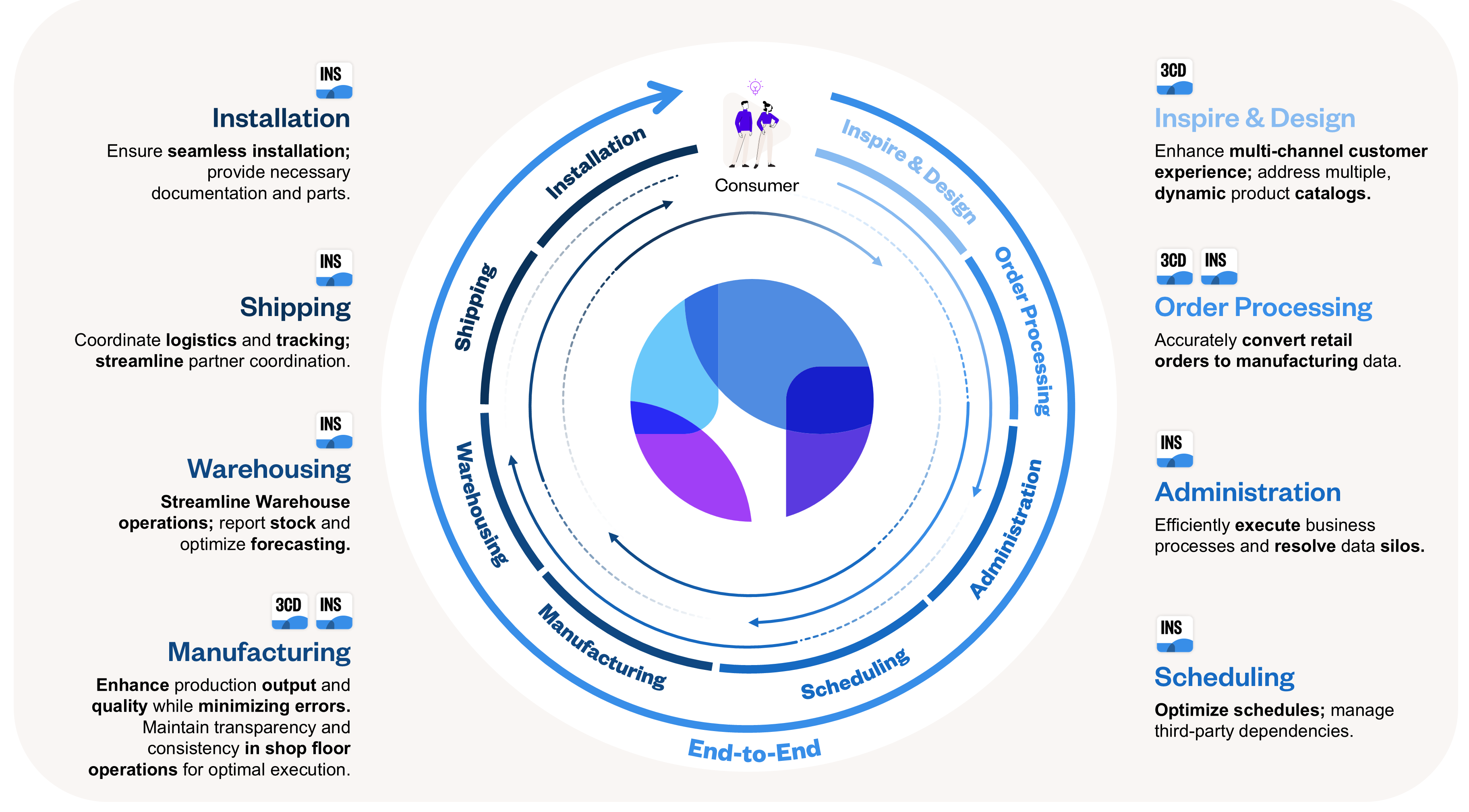

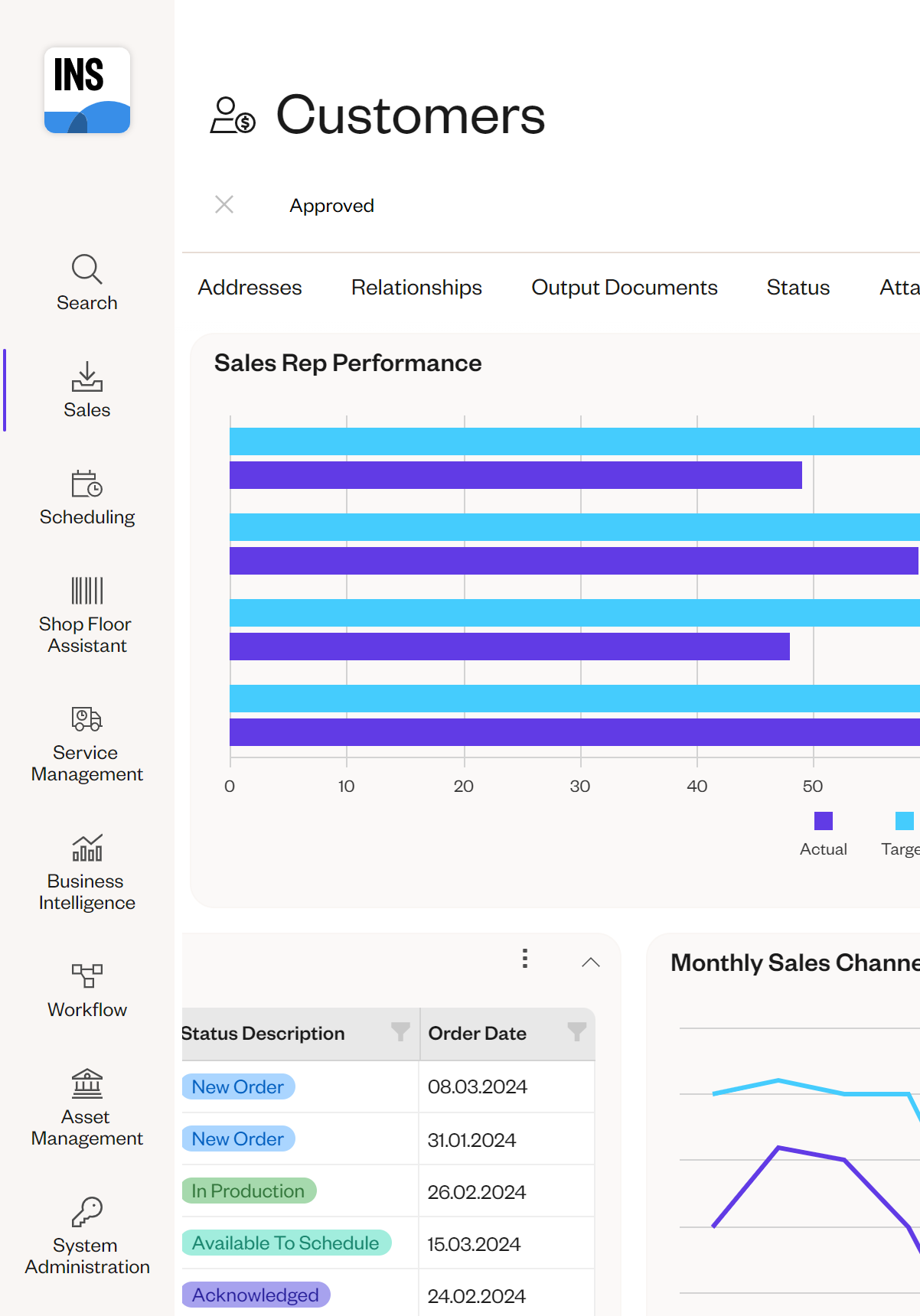

Cyncly’s cabinet manufacturing software connects your design, production, and business operations in a single system. With CAD, ERP, MES and WMS capabilities working together, you can move from inspiration to installation with fewer errors, faster lead times, and greater control.

Four pressures shaping the future of furniture manufacturing

How we help furniture and cabinet manufacturers build connected, modern operations